Our Products

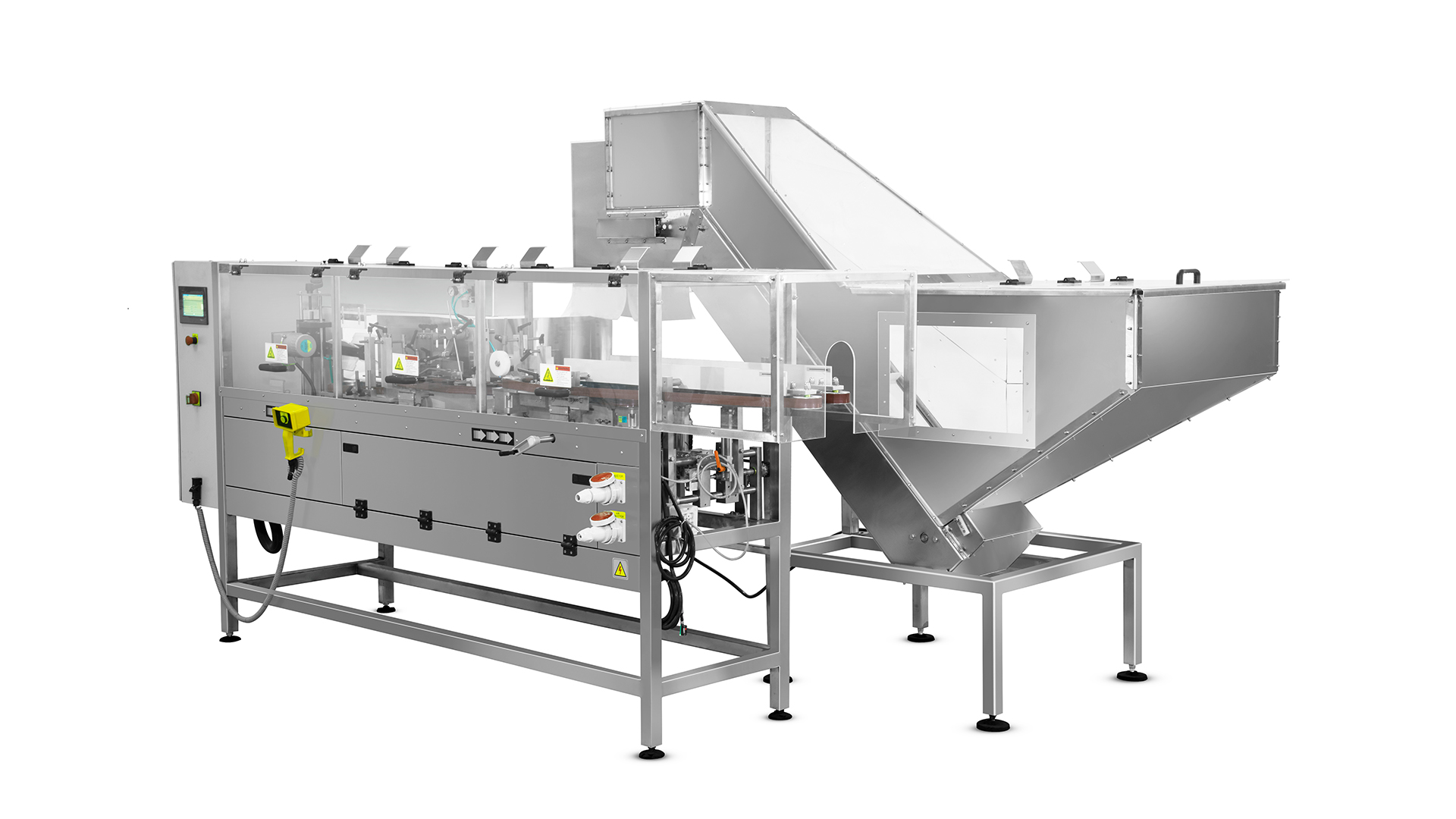

Robotic Unscrambler

Description

It Uses the latest technology advanced Codian D5 Robot for unscrambling and loading of bottles in pucks. Designed for high speed and performance, this one of its kind machine is capable of loading of any sort of shape and size of bottles on the pucks. The bottle only needs to be fed into the bulk bottle elevator from where it gets transferred to the transparent belt conveyor and the robot picks the bottles from there and transfers them into the pucks on the parallel running worm conveyor.

FEATURES

- Programmable Logic Controllers.

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Large working range.

- Positional repeatability upto 0.1 mm.

- Payload upto 1.5 Kg.

OUTPUT

Upto 24000 BPH

Rotary Unscrambler

FEATURES

- Programmable Logic Controllers.

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Easy control and low operating cost.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Description

Composed of round silo, umbrella tower, bottle drop device, and drive system, this unscrambler’s working principle is to arrange the empty PET bottles in hopper through centrifugal force and orientation bottle drop device and send them out to connect with air conveyor system. In addition, bottle elevator is equipped to send the empty PET bottles to the top of main machine.

Description

Composed of round silo, umbrella tower, bottle drop device, and drive system, this unscrambler’s working principle is to arrange the empty PET bottles in hopper through centrifugal force and orientation bottle drop device and send them out to connect with air conveyor system. In addition, bottle elevator is equipped to send the empty PET bottles to the top of main machine.

FEATURES

- Programmable Logic Controllers.

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Easy control and low operating cost.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

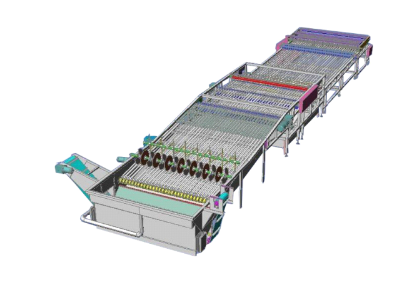

Linear Unscrambler

Description

It is built for unscrambling or straightening –up of PET bottles from bulk on to the conveyors for filling and capping. Using a simple yet effective mechanism of the relative motion of infeed, mid-feed and outfeed belt system and pneumatically actuated lifter rod, this machine is capable to handle bottles with varying shapes and sizes. Also the large size of the feeder and elevator makes it easy to refill.

FEATURES

- Programmable Logic Controllers.

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Easy control and low operating cost.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Glass Bottle Unscrambler

FEATURES

- Programmable Logic Controllers.

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Easy control and low operating cost.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Description

The Glass bottle unscrambler is a perfect substitute for the traditional bottle unscrambling method featuring manual case insertion and bottle loading, symbolizing a revolution for the liberation of labor in the bottle yard of breweries. It is possible to reduce investment in recycled plastic cases, decorators, and conveyor belts, reduce the occupied space of the bottle yard, assure the satisfaction of production requirements, and improved productivity.

It is used to feed upright glass bottles to the conveyor belts in a smooth and steady manner which then delivers glass bottles to the bottle washer.

It is used to feed upright glass bottles to the conveyor belts in a smooth and steady manner which then delivers glass bottles to the bottle washer.

Description

The Glass bottle unscrambler is a perfect substitute for the traditional bottle unscrambling method featuring manual case insertion and bottle loading, symbolizing a revolution for the liberation of labor in the bottle yard of breweries. It is possible to reduce investment in recycled plastic cases, decorators, and conveyor belts, reduce the occupied space of the bottle yard, assure the satisfaction of production requirements, and improved productivity.

It is used to feed upright glass bottles to the conveyor belts in a smooth and steady manner which then delivers glass bottles to the bottle washer.

It is used to feed upright glass bottles to the conveyor belts in a smooth and steady manner which then delivers glass bottles to the bottle washer.

FEATURES

- Programmable Logic Controllers.

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Easy control and low operating cost.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH