Our Products

Pressure Sensitive / Sticker Labeler

Linear labeler

Description

TechMatic-LM

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Floor level access to all machine parts

- Quick and easy roll changing.

- Special label sensor for detection of film transparent labels

- Optional registration features to cater for specific labeling requirements

OUTPUT

Upto 24000 BPH

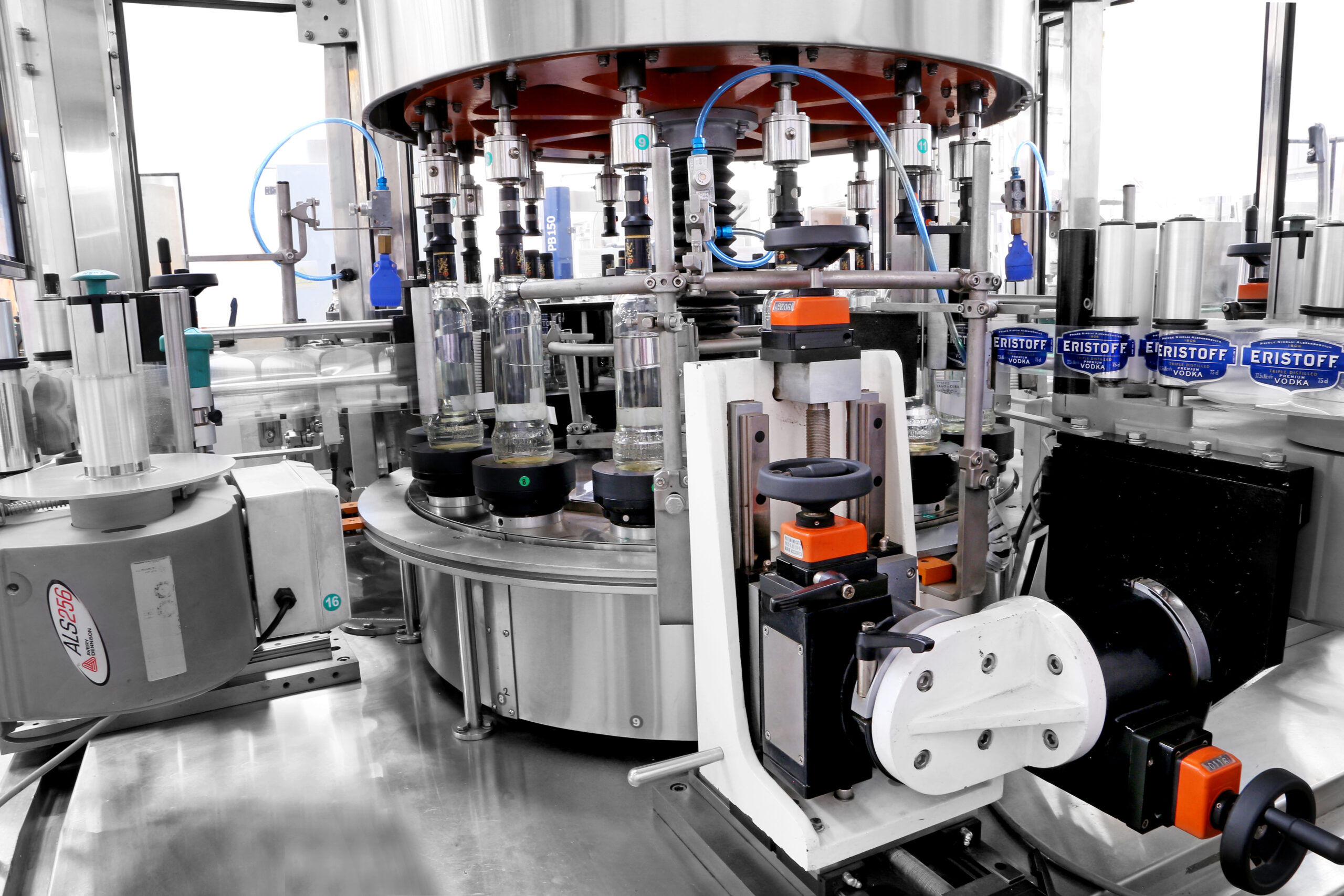

Rotary Labeler

Description

TechMatic-RM

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Floor level access to all machine parts

- Quick and easy roll changing.

- Special label sensor for detection of film transparent labels

- Optional registration features to cater for specific labeling requirements

OUTPUT

Upto 24000 BPH

Cold Glue Labeler

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI.

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Floor level access to all machine parts

- Easy control and low operating cost

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Optional registration features to cater for specific labelling requirements

- No bottle No Glue No label

- Robust, durable construction for long-lasting performance

OUTPUT

Upto 24000 BPH

Description

MultiMatic-RW

This machine is basically used for gluing paper labels onto the bottles. The cam-based chamber mechanism transfers the paper label from the rack on ‘magazine’ to the assembly where the glue is applied to the backside of label by gum roller and then it is passed onto the bottle and then pressed by rollers.

- RowMatic-LW

Description

MultiMatic-RW

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI.

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Floor level access to all machine parts

- Easy control and low operating cost

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Optional registration features to cater for specific labelling requirements

- No bottle No Glue No label

- Robust, durable construction for long-lasting performance

OUTPUT

Upto 24000 BPH

BOPP labeler

Description

RollMatic-LM

This machine is available in Linear as well as Rotary versions.

FEATURES

• Programmable Logic Controllers

• Machine designed entirely with stainless steel

• Motorised adjustment for bottles of various heights

• The entire machine can be flushed

• S type of curve labelling, Drum labelling at one time. The precision reaches to ± 0.5~ 1mm high accuracy.

• Both filled bottles and empty bottles are available.

• Straight-Ling labelling, smart design and easy bottle changing

APPLICATION

Generally used for mineral water, milk, soymilk, yogurt’s PET, PVC, PE, HDPE bottle wrap-round labelling with OPP web

Roll-fed labelers can accommodate a wide range of container types, sizes and label materials.

OUTPUT

Upto 24000 BPH

Sleever/Sleeving

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Floor level access to all machine parts

- Quick and easy roll changing.

- Motorized adjustment for bottles of various heights

- Special label sensor for detection of film transparent labels.

- Optional registration features to cater for specific labelling requirements.

OUTPUT

Upto 24000 BPH

Description

SleeveMat-SM

Description

SleeveMat-SM

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Floor level access to all machine parts

- Quick and easy roll changing.

- Motorized adjustment for bottles of various heights

- Special label sensor for detection of film transparent labels.

- Optional registration features to cater for specific labelling requirements.

OUTPUT

Upto 24000 BPH