Our Products

Rotary Blower

Description

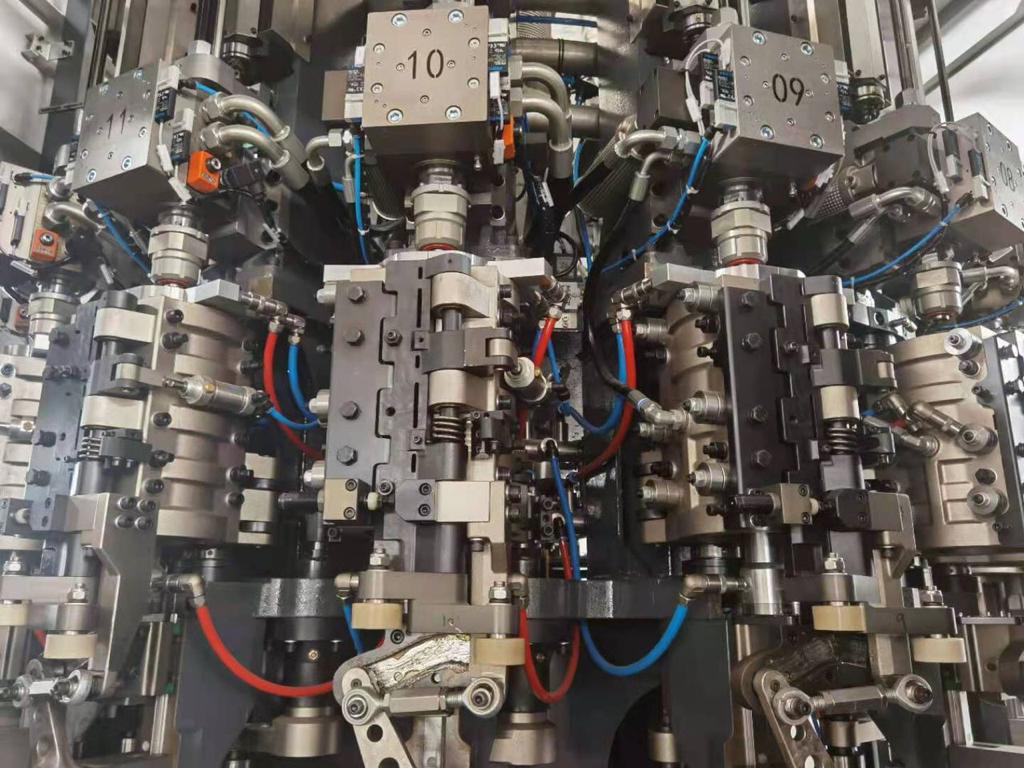

In this rotary type blowing machine, the contiform is heated and then blown into bottles by a high pressure jet of air. It starts with the preforms being dumped in bulk into a hopper from where it gets carried by elevator to the contiform carrying assembly which carries it to the heating and ionising assembly through a chute.

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI.

- 3-level Password protection

- Versatility in blowing many bottle formats and sizes on same machine by changing the die.

- Machine designed entirely with stainless steel.

- Water re-circulation to prevent overheating.

- Easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks

- Optional registration features to cater for specific requirements

- Dust blow-off with ionized air and suction.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

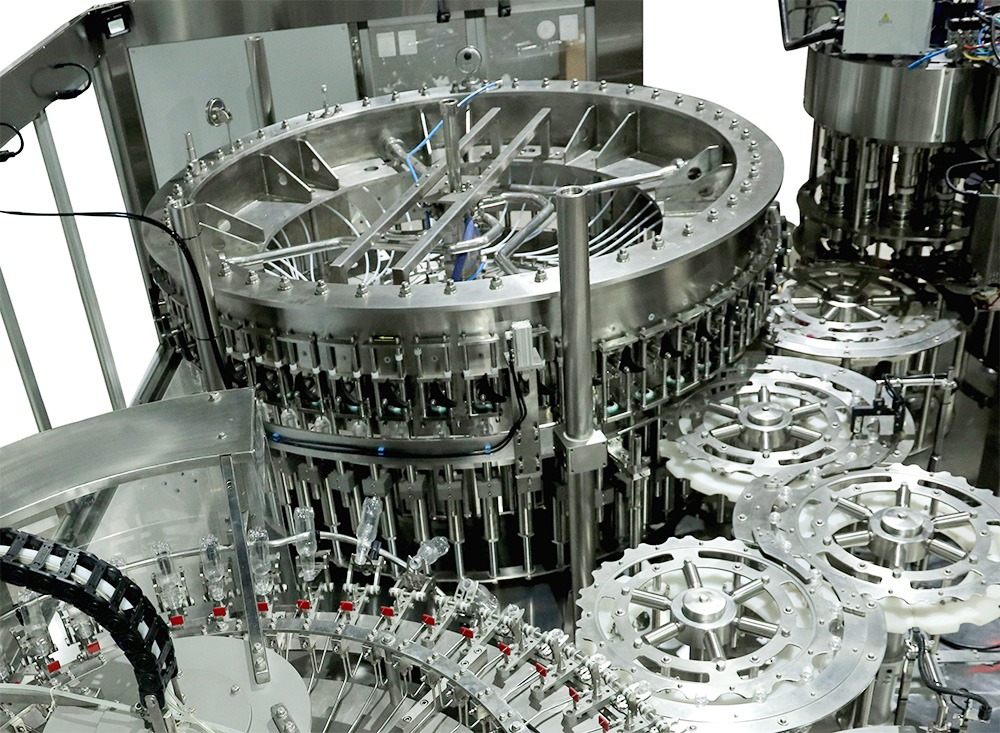

BlowTech (Blow, Fill, Cap)

Blow Molding

Blow molding system is characterizes by its reasonable structure, Lower power consumption, good stability, flexible blowing process and simple operation, especially on then production of drinking water, carbonated beverages and other common PET bottles.

Description

Blow Fill Cap technology represents an advanced method of manufacturing wherein a container is formed, filled and sealed through continuous and automated system. In this rotary type blowing machine, the contiform is heated and then blown into bottles by a high pressure jet of air. It starts with the preforms being dumped in bulk into a hopper from where it gets carried by elevator to the contiform carrying assembly which carries it to the heating and ionising assembly through a chute.

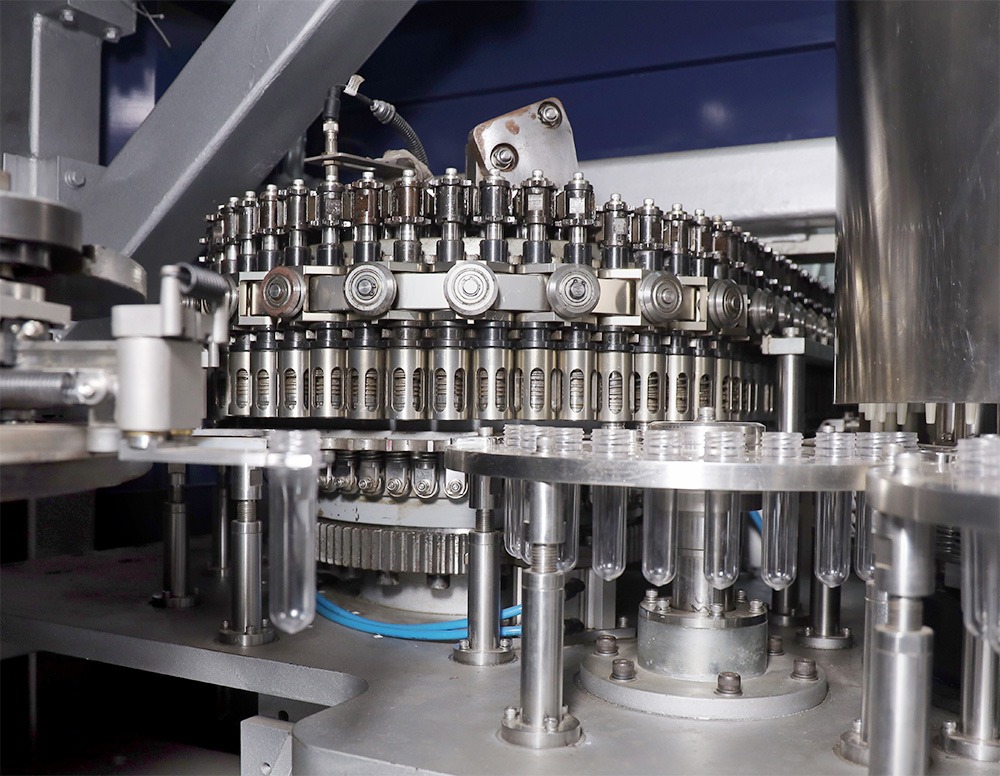

Filler And Capper

Once the container is formed and cooled it moves to the filling station. Product will be filled into the bottles automatically. After filling container top is sealed with caps. it’s a pick and place mechanism with magnetic capping heads.

FEATURES

- Programmable Logic Controllers

- Comprehensible and user-friendly HMI.

- 3-level Password protection

- Versatility in blowing many bottle formats and sizes on same machine by changing the die.

- Machine designed entirely with stainless steel.

- Water re-circulation to prevent overheating.

- Easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks

- Optional registration features to cater for specific requirements

- Dust blow-off with ionized air and suction.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH