Our Products

Gravity Fillers

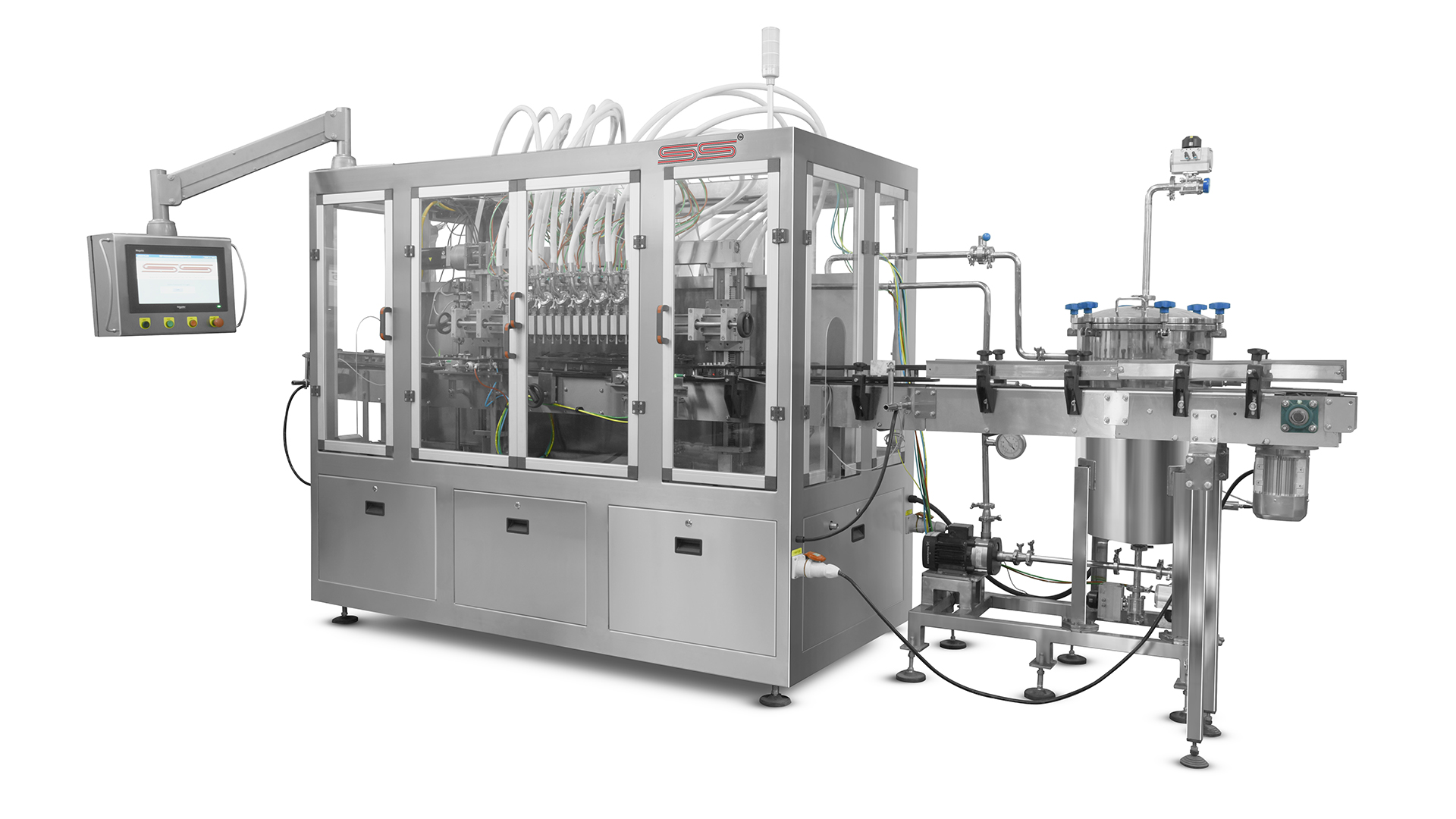

Gravity filler

Description

GraviTech

- Automatic Linear

- Automatic Rotary

- Semi-Automatic

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Vaccum filler

Description

VacuumTech

- Automatic Linear

- Automatic Rotary

- Semi-Automatic

OUTPUT

Upto 24000 BPH

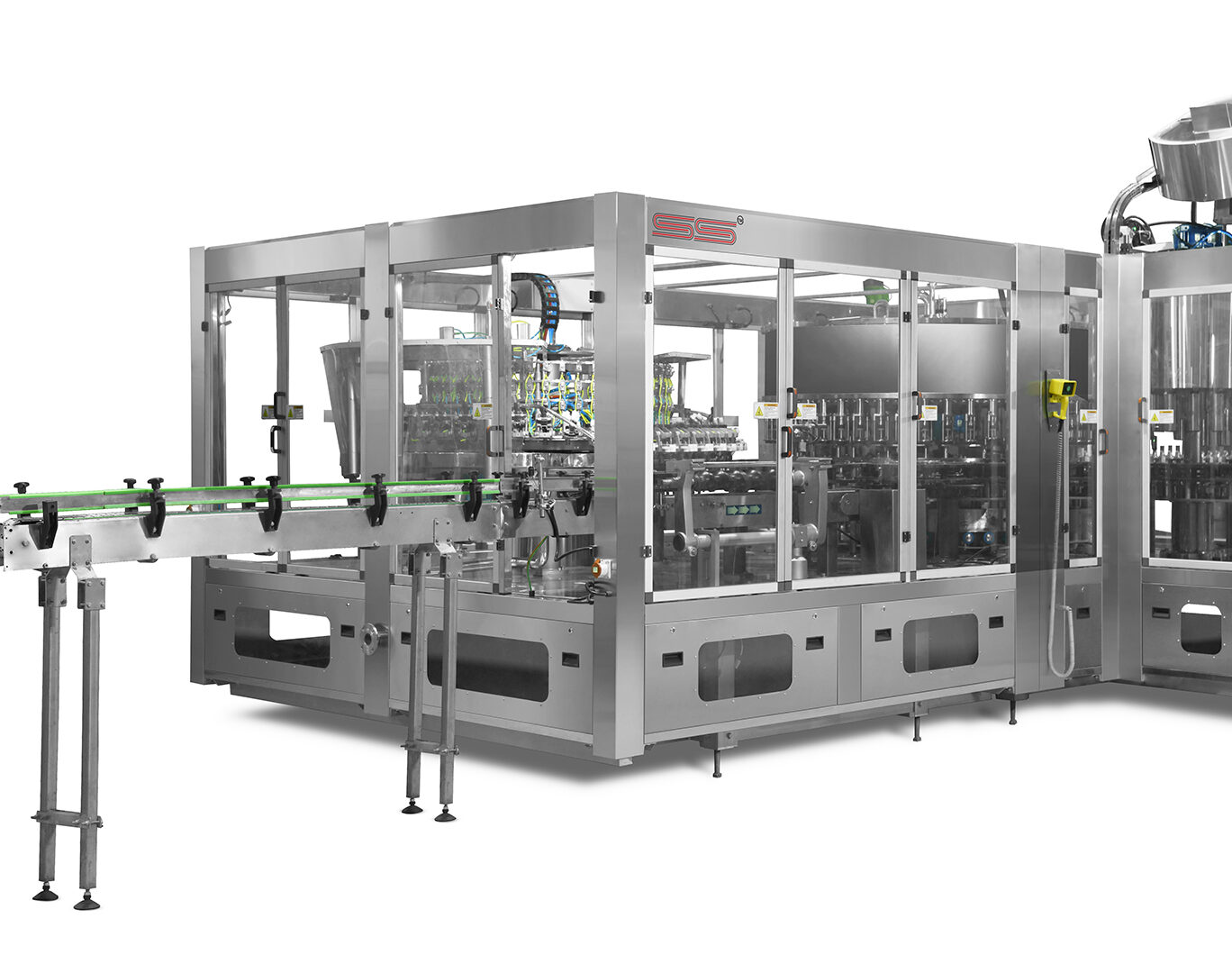

Monoblocs

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Description

These machines are a combination of any two of the rinser, filler and capper on a single body.

- ViscoBloc

- ViscoBloc Pro

- WeigBloc

- WeighBloc Pro

- GraviBloc

- FlowBloc

- VaccumBloc

Description

These machines are a combination of any two of the rinser, filler and capper on a single body.

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

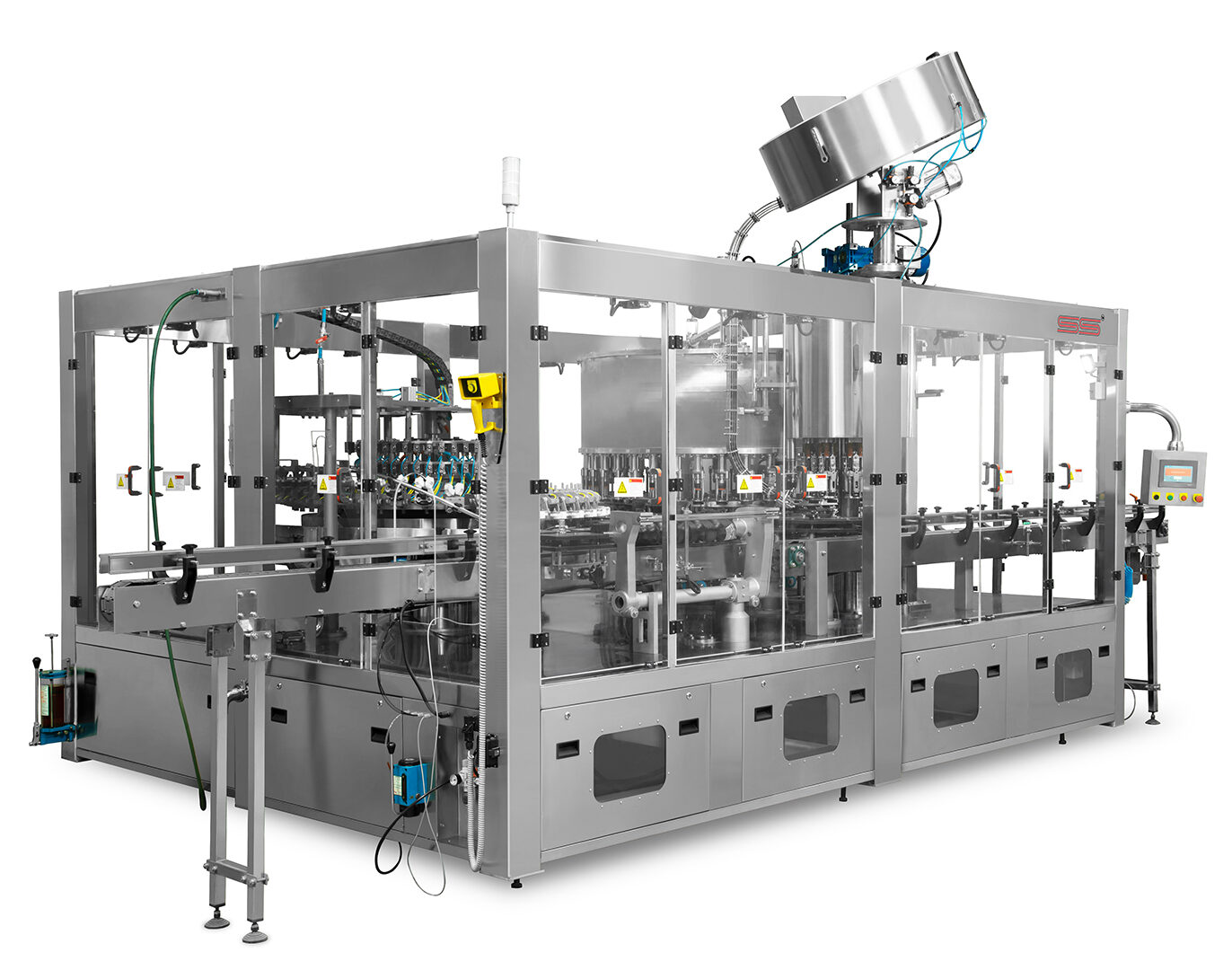

Uniblocs

Description

TrioMaster

Rinser Section: It is a versatile rotary bottle washing solution with upto 5 stages of rinsing with any media. The loading and unloading of bottles is done automatically via conveyors. As the number of heads of the machine increases, so does the output of the machine.

Filler section:

- Gravity fillers

- Vacuum fillers

- Electronic fillers

- Piston fillers

- Carbonated fillers

- Capper section:

- Screw capper

- ROPP capper

- Crown capper

- Guala capper

- Cork capper

- Pump capper

- Foil sealing

- Single head automatic capper

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Combibloc

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Description

Description

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Carbonated Fillers

Carbonated filler:

Description

IsoBev

An isobaric filling machine works on a thermodynamic process in which the pressure remains constant. In the case of isobaric filling, a back pressure similar to the one present inside the supply tank is generated inside the bottle, in order to perform a fast and effective filling.

We are able to propose clients Isobaric machines with higher-than-average performance levels, foamless or controlled foam filling even at temperatures of around 15°C. For different type of liquids like beer, water, soft drinks, sparkling wine, sparkling juice etc.

The technology is for controlled filling. Isobaric technology is implemented not only to fill glass bottles using a traditional system, but also PET bottles using a Neck Handling system.

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Can Fillers

FEATURES

- Reliable calculation of the fill level

- Low-oxygen filling thanks to CO² flushing

- Closed CIP circuit

- Electro-pneumatically controlled filling valve functions for maximum flexibility, managed by the operator on the main control panel.

- Possible to handle various sizes of cans ranging 150ml to 1000ml with change over partsGreat contingency in case of fill valve failure to allow production to keep moving.

OUTPUT

Upto 24000 BPH

Description

You can handle different size cans with this line. It is an extremely flexible & versatile machine.

Based on the electro-pneumatic control of the filling valves, offer high-speed precision filling and, in the case of beer and cider filling, minimal DO pickup levels.

Automatic counterpressure filling lines for cans. Suitable for filling beer, wine and carbonated drinks, it features our new EPV (Electro Pneumatic Valve) technology.

The valve allows total flexibility in adjusting the filling cycle by adapting the filling and degassing timings to the necessity of each different carbonated drink.

Description

You can handle different size cans with this line. It is an extremely flexible & versatile machine.

Based on the electro-pneumatic control of the filling valves, offer high-speed precision filling and, in the case of beer and cider filling, minimal DO pickup levels.

Automatic counterpressure filling lines for cans. Suitable for filling beer, wine and carbonated drinks, it features our new EPV (Electro Pneumatic Valve) technology.

The valve allows total flexibility in adjusting the filling cycle by adapting the filling and degassing timings to the necessity of each different carbonated drink.

- Reliable calculation of the fill level

- Low-oxygen filling thanks to CO² flushing

- Closed CIP circuit

- Electro-pneumatically controlled filling valve functions for maximum flexibility, managed by the operator on the main control panel.

- Possible to handle various sizes of cans ranging 150ml to 1000ml with change over partsGreat contingency in case of fill valve failure to allow production to keep moving.

OUTPUT

Upto 24000 BPH

Electronic Fillers

Flowmeter filler

Description

FlowTech

These fillers are suited for products that require very high level of filling accuracy in terms of mass or volume. The two technologies used are flowmeter and load cells. The former one incorporates Coriolis flow meter for high accuracy filling both in grams and ml, whereas the latter uses weigh pack load cells that measures tare and filled bottle weighs and time. It has provision to reject the bottles also that weigh more than the range specified.The models are:

-

- Load Cell Based

- Flowmeter Based

- Rotary

- Linear

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

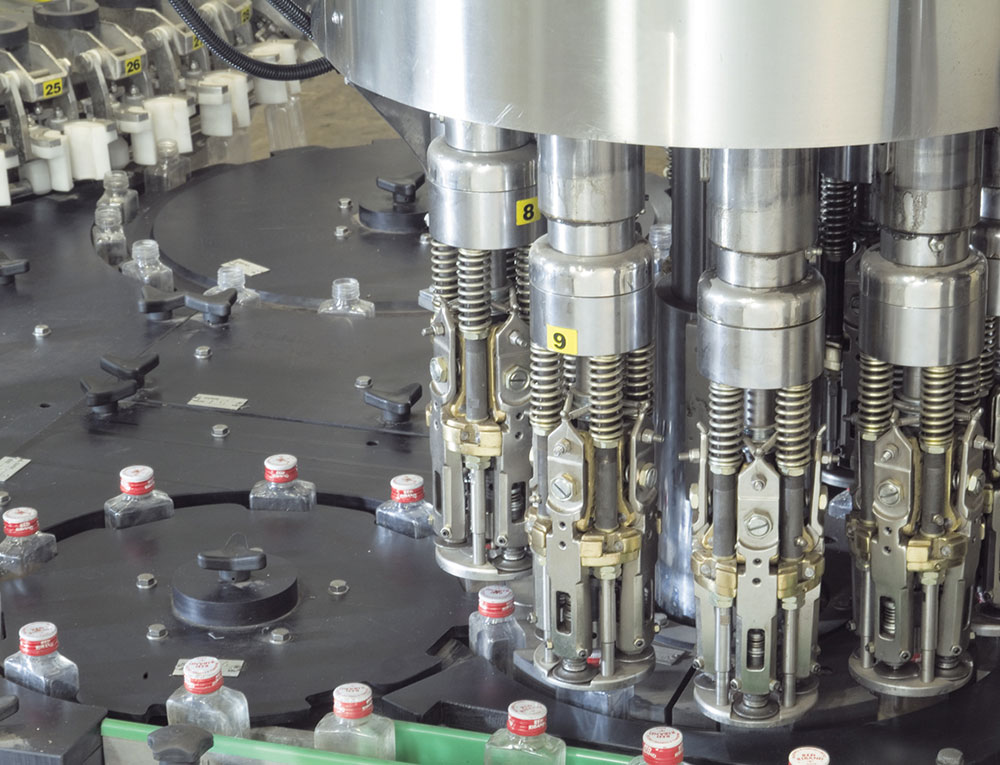

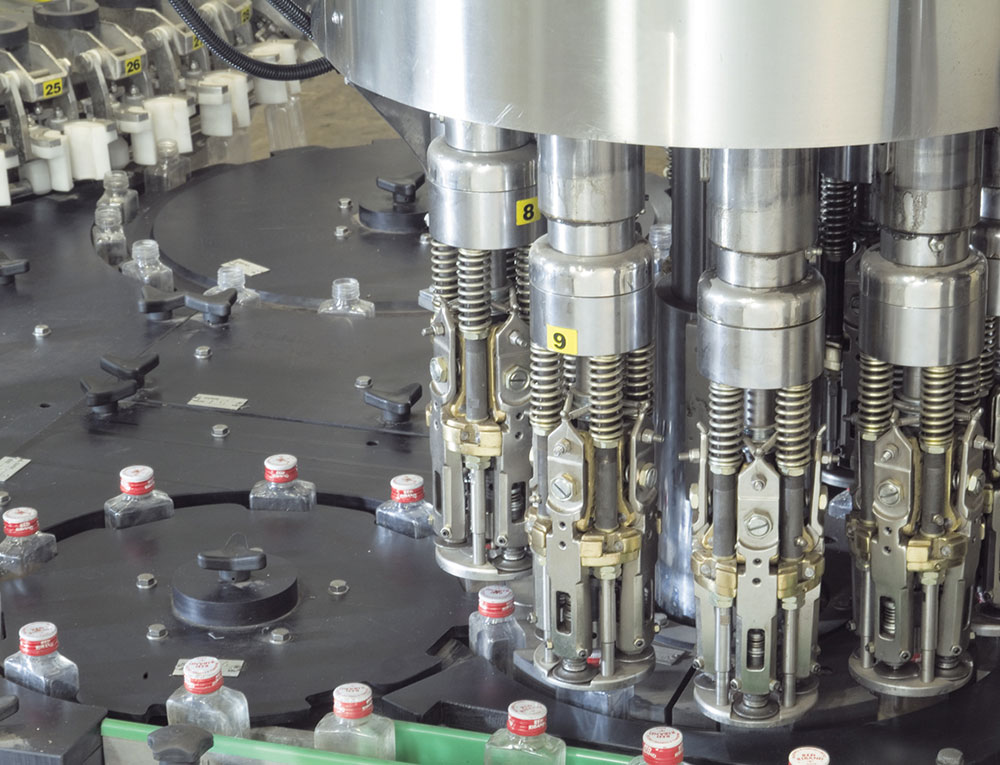

Netweight filler

Description

WeighTech

Net Weight Filling Technology is know as one of the most reliable solutions in the filling and packaging industry. SSP, manufactures these machines in collaboration with Weightpack Srl, the experts who were the first to introduce the Net-Weight Filler with electronic control in the Packaging Industry. The company has its roots in the early years of the last century.

These fillers are suited for products that require very high level of filling accuracy in terms of mass or volume. The two technologies used are flowmeter and load cells. The former one incorporates Coriolis flow meter for high accuracy filling both in grams and ml, whereas the latter uses weigh pack load cells that measures tare and filled bottle weighs and time. It has provision to reject the bottles also that weigh more than the range specified.

Net Weight Fillers can be used to fill wide range of viscocity products, with accurate fill constant with time, proper control of the weight of empty containers, complete washable and protected design, every station working independently, continous fill precision, electronic auto corection of the filling weight for every fill station, electonic auto Net Weight Filler Accurate fill which is constant with time, due to the continuous resetting of the weight system on each rotation of the filler.

OUTPUT

Upto 24000 BPH

Volumetric Fillers

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Description

Description

FEATURES

- Programmable logical controllers

- Comprehensible and user-friendly HMI

- 3-level Password protection

- Customisation options: the number of media channels, filling heads etc.

- Versatility in running many bottle formats and sizes on same machine Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles.

- Machine designed entirely with stainless steel

- Motorised adjustment for bottles of various heights.

- Extensive manpower saving.

- Cost-effective, easy control and low operating cost.

- Centralized lubrication system is set for lubrication at right time and right place with right dosing.

- Safety interlocks.

- Robust, durable construction for long-lasting performance.

OUTPUT

Upto 24000 BPH

Hot Filling

Description

Special filling valves allows HOT Filling also in non-crystallised PET bottles.

Special filling valves allows HOT Filling also in non-crystallised PET bottles.

OUTPUT

Upto 24000 BPH